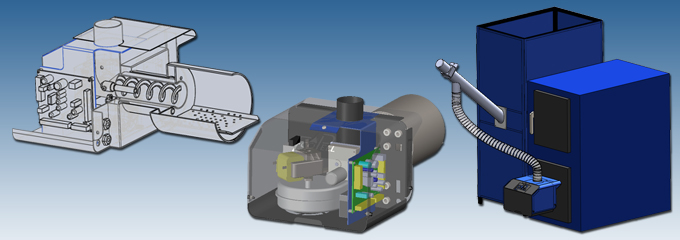

Pellet burner EcoPell ECO-35

The EcoPell ECO-35 pellet burner can be mounted on most central heating individual systems using hard and liquid fuels. The quality and reliability of the installed components guarantee the long life of our products and therefore the warranty period for the burner ECO-35 is two years from the installation date.

The EcoPell ECO-35 set consists of the burner, control unit, exterior fuel feeder and hopper.

The burner contains an internal fuel feed system which doses the pellets into the combustion chamber. Such construction guarantees protection from backfire and the internal fuel feeder doses pellets with more precision into the combustion chamber.

The electronic control unit is the „brain“ of this device and has been designed to provide convenient simple use of the set during the whole heating season. It performs all necessary temperature readings, controls dosage and fuel and air quantities according to current parameters. Besides controlling the burner, it also enables the user to manage, change the motion as well as the combustion parameters.

The whole system is completely automated and can be programmed for each day of the week. A GSM module can be attached to the electronic control panel and using test messages or EcoPell-droid applications, parameters which are important for the performance and adjustments of the whole system can be entered.

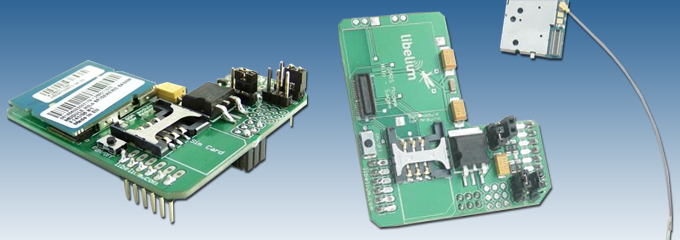

GSM/GPRS module

The GSM/GPRS module is designed for communication with the electronic control panel using text messages or EcoPell-droid applications. Telephone numbers from which requests and reports are received are entered into the control electronic panel.

Text message communication is performed by sending it to the electronics, recognizing and realizing it and then sending back data requested by the user.

Communication using the EcoPell-droid application is designed to show all the parameters and adjustments made on the burner.

The first page of the application shows the following parameters:

*Time of data update

*Burner switch (the switch setting can be changed)

*System time on the electronic control panel

*Burner status, current burner operating cycle

*Set water temperature in the furnace (the temperature can be reset)

*Current water temperature in the furnace

*Timer switch (the timer setting can be changed)

The second page of applications shows timers. Several timer settings can be preset and extracted from the telephone memory.

There are nine timer settings with the following parameters:

*Settings for a particular day (one or more days can be selected)

*Burner switch (settings which turn the burner on or off)

*Initial and final time of a setting

*Follow up of the designated temperature in the main menu or within the condition

*Temperature setting within the timer conditions

The third page of applications shows the burner operating log. The log shows all the work cycles the burner had gone through as far back as the user requests.

The fourth page of the applications shows all the parameters located in the sub-menu of the Settings.